Flanges

WHAT IS A FLANGE

An Industrial Pipe Flange can be a collar, ring or solid disk that attaches to various pipe applications that allow or restrict the flow of liquids and gases. Pipe Flange installment is usually completed by welding the Flange onto the pipe but the Industry also offers Threaded and Lap Joint Flanges that don’t require welding for installment.

Flange connections are achieved by drilling equally spaced bolt holes into the Flange that align with the matching Flange and then fastened with bolts. Bolt hole patterns are determined by Industry Specifications or customer request. Flanges are usually manufactured based on Industry Specifications established by ANSI B16.5, ASME B16.47, MSS-SP44, API, and AWWA-C207.

Pipe Flanges Materials and Grades

| Stainless Steel Pipe Flange |

| ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H,904L |

| Carbon Steel Pipe Flange |

| ASTM / ASME A/SA 105 ASTM / ASME A 350 , ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52 |

| Low Temperature Pipe Flange |

| ASTM A350 LF2, LF3, LF6 |

| Alloy Steel Pipe Flange |

| ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91 |

| Duplex & Super Duplex Steel Pipe Flange |

| ASTM / ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61 |

| Nickel Alloy Pipe Flange |

| UNS 10276 (HASTELLOY C 276), UNS 6625 (INCONEL 625), UNS 6601 (INCONEL 601), UNS 6600 (INCONEL 600), UNS 8825 (INCONEL 825), UNS 8020 (ALLOY 20 / 20 CB 3), UNS 4400 (MONEL 400), UNS 2201 (NICKEL 201), ASTM / ASME SB 336 UNS 2200 (NICKEL 200) |

| High Yield Pipe Flanges |

| ASTM A694 F42, F52, F60, F65, F70 |

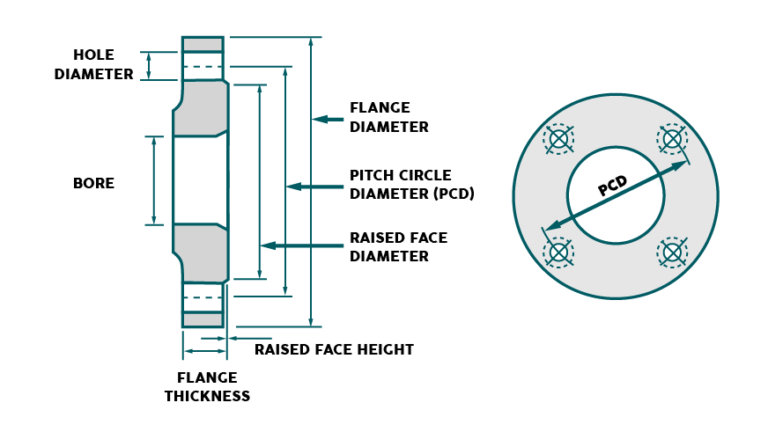

Measurements of Pipe Flange

Accurate measurement also relies on understanding pressure ratings. For a regular pipe flanges, first measure the flanges outside diameters (O.D). This will be accomplished by measuring from the surface edge of the flange to the other outer edge. Next, measure the within diameter of your flange. Steel Pipe Flanges within equivalent standards can either be flat or raised face.

Pipe Size – Pipe Flanges even have a corresponding pipe size, generally consistent with accepted standards.

Outside Diameter of Flange (OD) – this is often measured from outer edge to opposing outer edge.

Pitch Circle Diameter (PCD) – this is a diameter that measures from the middle of bolt hole to opposing bolt hole.

Flange Thickness – this measures only the thickness of the attaching outer rim, and doesn’t include the a part of the flange that holds the pipe.

Types of Pipe Flanges

Slip On Flange / SO Flange

Slip on Flange is essentially a ring that is placed over the pipe end, with the flange face extending from the end of the pipe by enough distance to apply a weld bead on the inside diameter. The OD of a slip-on flange is also welded on the back side of the Pipe flanges.

Weld Neck Flange / WN Flange

A weld neck flange (also known as a high-hub flange and tapered hub flange) is a type of flange. There are two designs. The regular type is used with pipes. The long type is unsuitable for pipes and is used in process plant.

Blind Flange / Blank Flange

A blind flange is a solid flange. The purpose of these is to block off a section of pipe or a nozzle on a vessel that is not used. (A nozzle is typically a pipe coming out of a vessel and is usually flanged so it can be connected to valves or piping).

Lap Joint Flange / LJ Flange

Lap joint flanges use a stub end that is welded to the pipe. A ring flange fits loosely around the stub end, permitting easy flange alignment of the bolt holes. A lap joint flange is also called Van Stone or Stub Flange. The stub ends are available in three styles (Types A, B, and C) and two lengths (Short and Long).

Threaded Neck Flange

Threaded Flanges are also known as a screwed flange, and it is having a thread inside the flange bore which fits on the pipe with matching male thread on the pipe. Threaded Flanges are mostly used in utility services such as air and water.

Socket Weld Flange

Socket-weld pipe flanges are typically used on smaller sizes of high-pressure pipes. These pipe flanges are attached by inserting the pipe into the socket end and applying fillet weld around the top. This allows for a smooth bore and better flow of the fluid or gas inside of the pipe.

Plate Flange / Flat Flange

As the name suggests, Plate flange has a flat face. Flat face flanges are used when the counter-flanges are a flat face. This condition occurs mainly on connection to Cast Iron equipment, valves, and specialties. Full face gasket is used when a flat face flange is used.

Ring Joint Type Face / RTJ Flange

Ring joint type face flange has a specially designed grove in which metal gasket seat. This type of flange is used in high pressure and temperature services.

Spectacle Blind Flange

Spectacle and line blind flanges are similar to a blind flange but different because they fit between two flanges. Spectacle blind gets their name from similarity to pair or eye-glasses. Once side of spectacle blind is fully closed for complete flow shuts off, whereas the other end is open for full flow. In this setup, the blinds can be rotated without having to take the system apart. It also gives visual confirmation if the line is open or close.

Groove & Tongue Flanges

Groove & Tongue flange are referred to as either Groove & Tongue or Tongue. This is similar to a slip-on flange in outline, but the bore is Groove & Tongue, thus enabling assembly without welding. These threads are tapered in order to create a seal between the Groove & Tongue flange and the pipe as the tapers approach the same diameter. Groove & Tongue Flanges are used for special circumstances with their main advantage being that they can be attached to the pipe without welding.

Long Neck Weld Flanges

Long Neck Welding flanges (LWN) are similar to a standard Welding Neck flange, but the “Neck” is considerably longer. This type is often used as a nozzle for a barrel or column. In addition, there are the type LWN Heavy Barrel (HB) and the Equal LWN Barrel (E); they have a different shape and a thicker “Wall”.