EN 10219-1 welded pipes

EN 10219-1 specified for Cold formed welded structural hollow sections of non-alloy and fine grain steels

Garde: S235JRH,S275JOH,S275J2H,S355JOH,S355J2H,S355K2H

Type: Electric resistance welded(ERW)

Round Hollow Section/Structural Steel Tube:

OD: 21.3-1219mm WT: 2-30mm

Square Hollow Section/Square Steel Tube:

OD: 20 X 20 - 400 X 400mm WT: 2-40mm

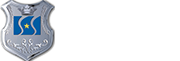

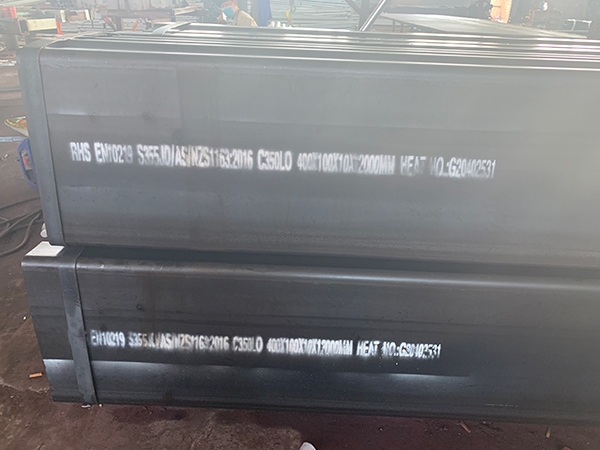

Rectangular Hollow Section/Rectangular Steel Tube:

OD: 40 X 20 - 400 X 300mm WT: 2-16mm

EN 10219-1 Chemical Analysis

|

Steel grade |

Type of de-oxidation a |

% by mass, maximum |

||||||

|

Steel name |

Steel number |

C |

C |

Si |

Mn |

P |

S |

Nb |

|

S235JRH |

1.0039 |

FF |

0,17 |

— |

1,40 |

0,040 |

0,040 |

0.009 |

|

S275J0H |

1.0149 |

FF |

0,20 |

— |

1,50 |

0,035 |

0,035 |

0,009 |

|

S275J2H |

1.0138 |

FF |

0,20 |

— |

1,50 |

0,030 |

0,030 |

— |

|

S355J0H |

1.0547 |

FF |

0,22 |

0,55 |

1,60 |

0,035 |

0,035 |

0,009 |

|

S355J2H |

1.0576 |

FF |

0,22 |

0,55 |

1,60 |

0,030 |

0,030 |

— |

|

S355K2H |

1.0512 |

FF |

0,22 |

0,55 |

1,60 |

0,030 |

0,030 |

— |

| a. The deoxidation method is designated as follows:FF: Fully killed steel containing nitrogen binding elements in amounts sufficient to bind available nitrogen (e.g. min. 0,020 % total Al or 0,015 % soluble Al).

b. The maximum value for nitrogen does not apply if the chemical composition shows a minimum total Al content of 0,020 % with a minimum Al/N ratio of 2:1, or if sufficient other N-binding elements are present. The N-binding elements shall be recorded in the Inspection Document. |

||||||||

The tolerances on dimensions are established in accordance with EN 10219-1&2

| Characteristics | Tolerances | ||||

| Outside dimensions of side | (H,B100mm) | 1% with a min of 0.5mm | |||

| H : Longest side B : Shortest side |

(100mmH,B200mm) | 0.8% | |||

| (200mmH,B) | 0.6% | ||||

| Wall thickness(T) | (T5mm) | 10% | |||

| (5mmT) | 0.50mm | ||||

| Concavity / Convexity | MAX 0.8% with a min of 0.5mm | ||||

| Squareness of sides | 901 | ||||

| External corner radius | (T6mm) | 1.6TR2.4T | |||

| (6mmT10mm) | 2.0TR3.0T | ||||

| (10mmT) | 2.4TR3.6T | ||||

| Twist | 2mm + 0.5mm/m in length | ||||

| Straightness | 0.15% in total length | ||||

| Mass | 6% in individual lengths | ||||

| Length | Approximate | 0, +50mm | |||

| Exact | L6,000mm | 0, +5mm | |||

| 6,000mmL10,000mm | 0, +15mm | ||||

| 10,000mmL | 0, +5mm+1mm/m | ||||

| NOTE 1)The outside dimensions are measured across the flats at positions at least 50mm from the end of the HSS. |

|||||

| Steel Grade | Steel No. | Chemical Composition Limits (%) | |||||

| C Max. | Si Max. | Mn Max. | P Max. | S Max. | N Max. | ||

| S235JRH | 1.0039 | 0.17 | – | 1.40 | 0.040 | 0.040 | 0.009 |

| S275J0H | 1.0149 | 0.20 | – | 1.50 | 0.035 | 0.035 | 0.009 |

| S275J2H | 1.0138 | 0.20 | – | 1.50 | 0.030 | 0.030 | – |

| S355J0H | 1.0547 | 0.22 | 0.55 | 1.60 | 0.035 | 0.035 | 0.009 |

| S355J2H | 1.0576 | 0.22 | 0.55 | 1.60 | 0.030 | 0.030 | – |

| S355K2H | 1.0512 | 0.22 | 0.55 | 1.60 | 0.030 | 0.030 | – |

| Steel Grade | Steel No. | Mechanical Properties | Impact Energy (KV J) | ||||

| Yield Strength (Mpa) | Tensile Strength (Mpa) | Elongation (%) | Test Temperature At Test Temperature of ℃ | ||||

| -20 | 0 | 20 | |||||

| S235JRH | 1.0039 | 235 | 360-510 | 26 | – | – | 27 |

| S275J0H | 1.0149 | 275 | 410-560 | 23 | – | 27 | – |

| S275J2H | 1.0138 | 275 | 410-560 | 23 | 27 | – | – |

| S355J0H | 1.0547 | 355 | 510-680 | 22 | – | 27 | – |

| S355J2H | 1.0576 | 355 | 510-680 | 22 | 27 | – | – |

| S355K2H | 1.0512 | 355 | 510-680 | 22 | 40 | – | – |