Drill Pipe

Standards and technical conditions for supply:API SPEC 5DP The wear-resistant belt of tool joint: Arnco 100XT, 200XT, 300XT, 400XT Internal coating drill pipe: TK34, DPC, TC2000, TC3000

Standard: Drill pipe

Grade: E75, X95, G105, S135 .

The wear-resistant belt of tool joint: Arnco 100XT, 200XT, 300XT, 400XT

Internal coating drill pipe: TK34, DPC, TC2000, TC3000

Usage: Mine blasting, water well drilling, geothermal wells drilling, fore poling, coal and nonferrous metal mining projects, etc.

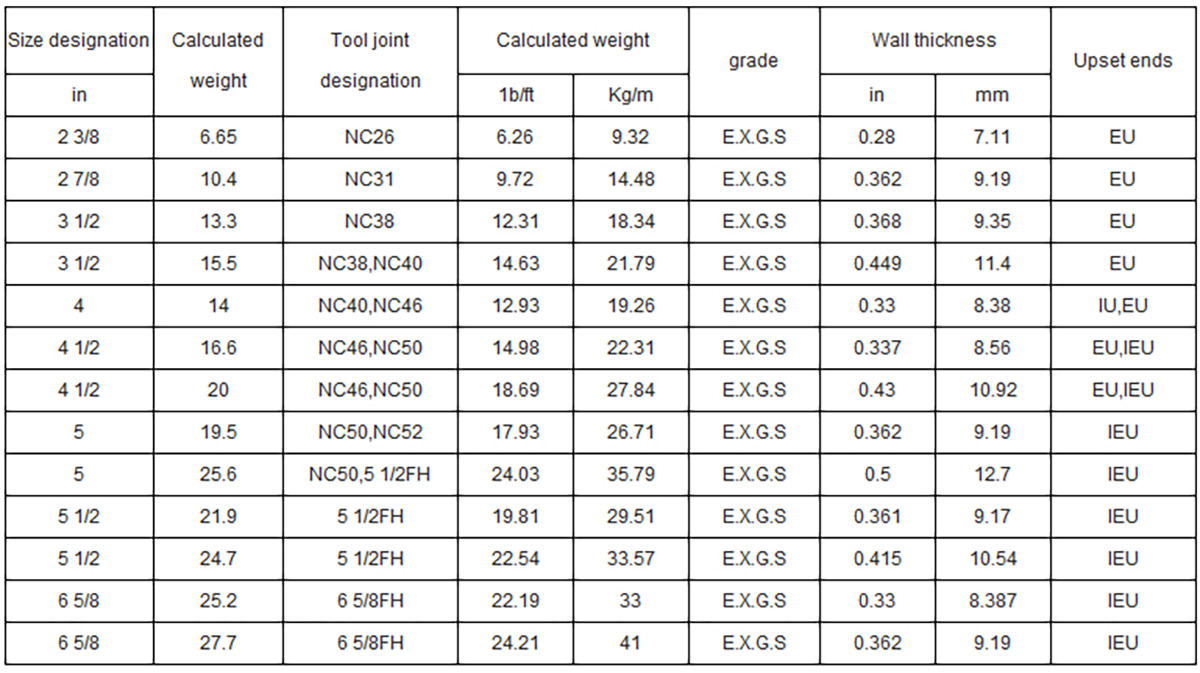

Dimension

Chemical Composition(%)

|

Grade |

Chemical composition |

|

|

P |

S |

|

|

E75 |

<0.015 |

<0.003 |

|

X95 |

<0.015 |

<0.003 |

|

G105 |

<0.015 |

<0.003 |

|

S135 |

<0.015 |

<0.003 |

|

Tool joint |

<0.015 |

<0.003 |

Mechanical Properties

|

Pipe body |

Grade |

Yield strength |

Tensile strength |

Elongation |

Hardness |

Full size charpy impact test(J) |

||||||

|

min |

max |

min |

min |

|||||||||

|

Psi |

MPa |

Psi |

MPa |

Psi |

MPa |

HBW |

HRC |

Average |

Single |

|||

|

E75 |

75000 |

517 |

105000 |

724 |

100000 |

689 |

625000A0.2/U0.9 |

- |

- |

80 |

65 |

|

|

X95 |

95000 |

655 |

125000 |

862 |

105000 |

724 |

- |

- |

80 |

65 |

||

|

G105 |

105000 |

724 |

135000 |

931 |

115000 |

793 |

- |

- |

80 |

65 |

||

|

S135 |

135000 |

931 |

165000 |

1138 |

145000 |

1000 |

- |

- |

80 |

65 |

||

|

Weld zone |

Tool joint |

120000 |

827.4 |

- |

- |

140000 |

965.3 |

=13% |

=285 |

- |

80 |

65 |

|

E75 |

75000 |

517 |

- |

- |

100000 |

689 |

- |

?37 |

40 |

27 |

||

|

X95 |

88000 |

609 |

- |

- |

103000 |

712 |

- |

?37 |

40 |

27 |

||

|

G105 |

95000 |

655 |

- |

- |

105000 |

724 |

- |

?37 |

40 |

27 |

||

|

S135 |

105000 |

724 |

- |

- |

115000 |

?37 |

40 |

27 |

||||

Drill Collars are integral heavy-wall joints that are manufactured from a solid bar of modified alloy steel. The solid bars are quenched and tempered to obtain the required mechanical properties, then trepanned, drifted and threaded. Drill collars are furnished as slick or spiraled in 30 or 31 foot lengths.

Slick drill collars are supplied with the mill as-rolled surface finish. Spiraled drill collars have grooves machined in the outside surface. The spiral grooves promote even flow of drilling fluid around the collar diameter, equalizing pressure and reducing the occurrence of differential sticking.