ASTM A789 A790 Pipe

Duplex Stainless Steel have a structure that contains both ferrite and austenite. Duplex alloys have higher strength and better stress corrosion cracking resistance than most austenitic alloys and greater toughness than ferritic alloys, especially at low temperatures. The corrosion resistance of duplex alloys depends primarily on their composition, especially the amount of chromium, molybdenum, and nitrogen they contain.

ASTM A789/ ASME SA789 covers seamless and welded ferritic/austenitic stainless steel tubing for general services. The standard also applied to duplex stainless steel tube material. All tubes in this standard shall be furnished with heat-treated condition according to specified temperature and quench conditions. When the final heat treatment is in a continuous furnace, or when heat treated condition is obitained directly by quenching after hot forming, the number of tubes of same size and from the same heat lot shall be determined from the prescribed sizes of the tubes.

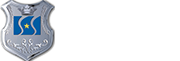

ASTM A790/ ASME SA790 is standard specification for seamless and welded ferritic/austenitic stainless steel pipe. Including duplex stainless steel pipe material. The standard specification mainly covers seamless and longitudinal weld ferritic/austenitic steel pipe, that applied intended for general corrosive services, with particular emphasis on resistance to stress corrosion cracking. This kind of pipe shall be manufactured by seamless or automatic welding process, without adding filler metal in the welding processes. Heat analysis shall be made to determine the percentages of the chemical elements specified. Tensile test, hardening test, flattening test, hydrostatic tests and nondestructive test shall be performed to the specified requirements.

Range

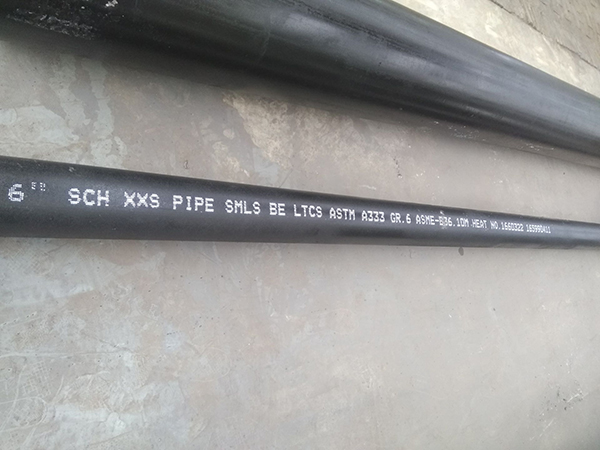

Standard: ASTM/ASME A/SA789, A/SA790, A/SA928, DIN17456/17458, EN10216-5. After negotiation, we can supply pipe with customers'requirement.

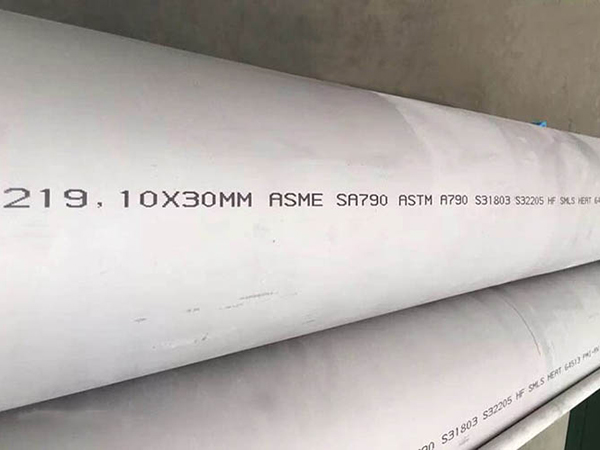

Material Grade:UNS 31803,S32205,S32101,S32304,S32750,S32760,1.4462,1.4410etc.

Size Range

| Stainless Steel Seamless Tube | ASTM A789/A789M: OD: Φ12.7mm-Φ203mm; WT:0.5mm-6.35mm |

| Stainless Steel Seamless Pipe | ASTM A790/A790M: OD: Φ6mm-Φ325mm; WT:0.5mm-30mm |

| Stainless Steel Welded Tube | ASTM A789/A789M: OD: Φ12.7mm-Φ203mm; WT:0.5mm-4.0mm |

| Stainless Steel Welded Pipe | ASTM A790/A790M: OD: Φ10mm-Φ2000mm; WT:0.5mm-40mm(OD≤630mm for single seam; OD>Φ630mm For circumferential seam) |

| ASTM A928/A928M: OD: Φ10mm-Φ406mm; WT:0.5mm-10mm |

ASTM A789/A790 Material Grade

|

UNS |

EN |

DIN |

C % |

Cr% |

Ni% |

Mo% |

N% |

Other % |

|

S31803 |

1.4462 |

X2CrNiMoN22-5-3 |

0.030max |

21.0-23.0 |

4.5-6.5 |

2.5-3.5 |

0.08-0.20 |

/ |

|

S32205 |

1.4462 |

X2CrNiMoN22-5-3 |

0.030max |

22.0-23.0 |

4.5-6.5 |

3.0-3.5 |

0.14-0.20 |

/ |

|

S32101 |

1.4162 |

|

0.040max |

21.0-22.0 |

1.35-1.70 |

0.10-0.80 |

0.20-0.25 |

Cu 0.10-0.80 |

|

S32304 |

|

|

0.030max |

21.5-24.5 |

3.0-5.5 |

0.05-0.60 |

0.15-0.20 |

Cu 0.05-0.60 |

|

S32750 |

1.4410 |

X2CrNiMoN25-7-4 |

0.030max |

24.0-26.0 |

6.0-8.0 |

3.0-5.0 |

0.24-0.32 |

Cu 0.50max |

|

S32760 |

|

|

0.050max |

24.0-26.0 |

6.0-8.0 |

3.0-4.0 |

0.20-0.30 |

Cu 0.50-1.00 |

ASTM A789/A790 Mechanical Property

| UNS | Tensile Strength Min, Mpa |

Yield Strength Min, Mpa |

Elongation in 2 in Or 50mm Min, % | Hardness Max, HRC |

| S31803 | 620 | 450 | 25 | 30 |

| S32205 | 655 | 485 | 25 | 30 |

| S32101 | 700 | 530 | 30 | 30 |

| S32304 | 690 | 450 | 25 | 30 |

| S32750 | 800 | 550 | 15 | 32 |

| S32760 | 750 | 550 | 25 | 32 |