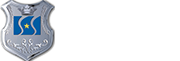

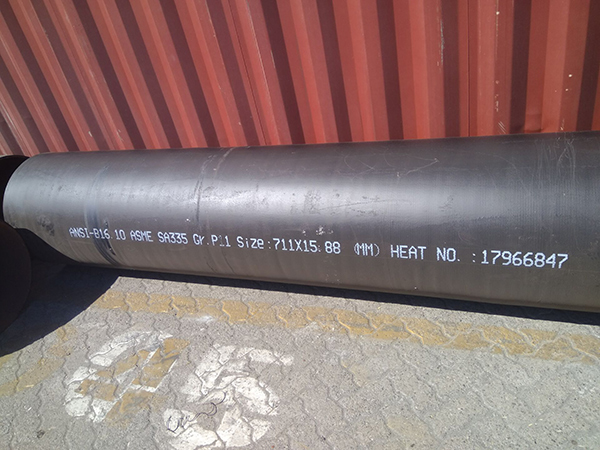

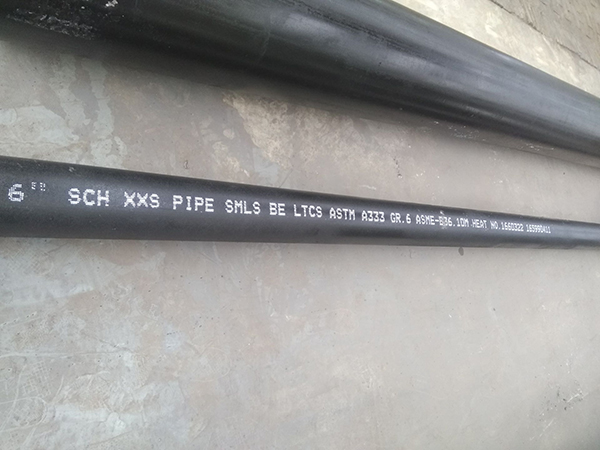

ASTM A335 Pipe

ASTM A335(or ASME SA335) is the standard specification for seamless ferritic alloy steel pipe for high temperature service. It covers steel grades from P1 to P5, P9, P11, P12, P91. Grades P11/P22 and P91/92 pipes are commonly used in power generation and petrochemical industries. ASTM A335 grade P5 and P9 pipes are mostly used for application in the petrochemical industry. Not only power generation and petrochemical industries, it is also applied to gas processing equipment, oil serves, heaters/reheat lines and boilers.

Features

● Strong resistance to rupturing at high temperatures and high pressures

● May be used for Hydrogen Sulfide Corrosion Services

● Resistant to cracking from hydrogen attack and embrittlement

● Resistant to hot sulfide corrosion cracking

● Can be used for NACE Applications where sour environments are under high temp and pressure

● Can be used in NACE-MRO 175 Sour Service

● Ideal for creep rupture applications

● Can handle high temperatures with very low elasticity

Size Range

OD 12.7-762mm

WT 2-120 mm

Chemical And Mechanical Properties

|

Material |

C |

Si |

Mn |

P |

S |

Mo |

Cr |

|

% |

% |

% |

% |

Max |

% |

% |

|

|

A335 Grade P1 |

0.10---0.20 |

0.10---0.50 |

0.30---0.80 |

0.025 |

0.025 |

0.44-0.65 |

/ |

|

A335 Grade P5 |

Max 0.15 |

Max 0.50 |

0.30---0.60 |

0.025 |

0.025 |

0.45-0.65 |

4.00-6.00 |

|

A335 Grade P9 |

Max 0.15 |

0.25-1.00 |

0.30---0.60 |

0.025 |

0.025 |

0.90-1.10 |

8.00-10.00 |

|

A335 Grade P11 |

0.05---0.15 |

0.5---1.0 |

0.30---0.60 |

0.025 |

0.025 |

0.45-0.65 |

1.00-1.50 |

|

A335 Grade P12 |

0.05---0.15 |

Max 0.50 |

0.30---0.61 |

0.025 |

0.025 |

0.45-0.65 |

0.80-1.25 |

|

A335 Grade P22 |

0.05---0.15 |

Max 0.50 |

0.30---0.60 |

0.025 |

0.025 |

0.87-1.13 |

1.90-2.60 |

|

A335 Grade P91 |

0.08-0.12 |

0.20-0.50 |

0.30---0.60 |

0.020 |

0.010 |

0.85-1.05 |

8.00-9.50 |

|

A335 Grade P92 |

0.07-0.13 |

Max 0.50 |

0.30---0.60 |

0.020 |

0.010 |

0.30-0.60 |

8.50-9.50 |

| Mechanical Property | P1,P2 | P12 | P91 | P92 | P122 | Others |

| Tensile strength ksi | 55 | 60 | 85 | 90 | 90 | 60 |

| Tensile strength mpa | 380 | 415 | 585 | 620 | 620 | 415 |

| Yield strength ksi | 30 | 32 | 60 | 64 | 58 | 30 |

| Yield strength mpa | 205 | 220 | 415 | 440 | 400 | 205 |

| Calculated minimum elongation values | ||||

| Elongation in 2in or 50mm, min% | ||||

| Wall thickness | P5,P9,P11,P22 | P91 | ||

| in | mm | Longitudinal | Transverse | Longitudinal |

|

5/16 (0.312) |

8 |

30 |

20 |

20 |

|

9/32 (0.281) |

7.2 |

28 |

19 |

19 |

|

1/4 (0.250) |

6.4 |

27 |

18 |

18 |

|

7/32 (0.219) |

5.6 |

26 |

/ |

17 |

|

3/16 (0.188) |

4.8 |

24 |

/ |

16 |

|

5/32 (0.156) |

4 |

22 |

/ |

15 |

|

7/8 (0.125) |

3.2 |

21 |

/ |

14 |

|

3/32 (0.094) |

2.4 |

20 |

/ |

13 |

|

1/18 (0.062) |

1.6 |

18 |

/ |

12 |

|

5/16 (0.312) |

8 |

30 |

20 |

20 |

| NPS(DN) Designator | Over | Under | ||

| in | mm | in | mm | |

|

1/8 to 1 1/2 [6 to 40], incl. |

1/64 (0.015) |

0.40 |

1/64 (0.015) |

0.40 |

|

Over 1 1/2 to 4 [40 to 100], incl. |

1/32 (0.031) |

0.79 |

1/32 (0.031) |

0.79 |

|

Over 4 to 8 [100 to 200], incl. |

1/16 (0.062) |

1.59 |

1/32 (0.031) |

0.79 |

|

Over 8 to 12 [200 to 300], incl. |

3/32 (0.093) |

2.38 |

1/32 (0.031) |

0.79 |

| Over 12 (300) | +/-1% of the specified outer diameter | |||

| NPS(DN) Designator | Tolerance, % from Specified | |

|

1/8 to 2 1/2 [6 to 65] incl., all t/D ratios |

20.0% |

12.5% |

|

Above 2 1/2 [65], t/D < or = 5% |

22.5% |

12.5% |

|

Above 2 1/2 [65], t/D > 5% |

15.0% |

12.5% |

|

1/8 to 2 1/2 [6 to 65] incl., all t/D ratios |

20.0% |

12.5% |

| (t = Specified Wall Thickness; D = Specified Outside Diameter) | ||

|

ASTM A335 Grade |

Heat Treatment Type |

Normalizing Temperature Range F [C] |

Subcritical Annealing or Tempering |

|

P5 |

Full or Isothermal Anneal |

||

|

P5 b |

Normalize and Temper |

- |

1250 [675] |

|

P5 c |

Subcritical Anneal (P5c only) |

- |

1325 - 1375 [715 - 745] |

|

P9

|

Full or Isothermal Anneal |

||

|

Normalize and Temper |

- |

1250 [675] |

|

|

P11

|

Full or Isothermal Anneal |

||

|

Normalize and Temper |

- |

1200 [650] |

|

|

P22

|

Full or Isothermal Anneal |

||

|

Normalize and Temper |

- |

1250 [675] |

|

|

P91

|

Normalize and Temper |

1900-1975 [1040 - 1080] |

1350-1470 [730 - 800] |

|

Quench and Temper |

1900-1975 [1040 - 1080] |

1350-1470 [730 - 800] |

Inspection And Test Performed

Chemical composition inspection, mechanical properties test ( Tensile strength, yield strength, elongation,Flattening, Hardness, or bend test) Surface and dimension test, Non-destructive test, Hydrostatic Test.

Packing and Delivery