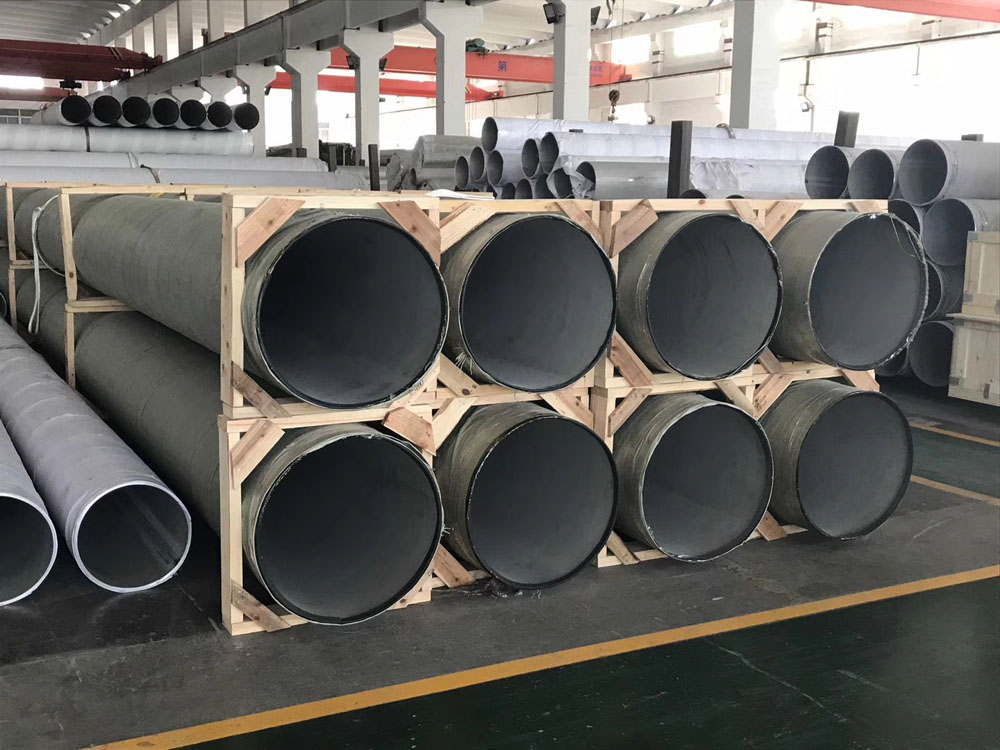

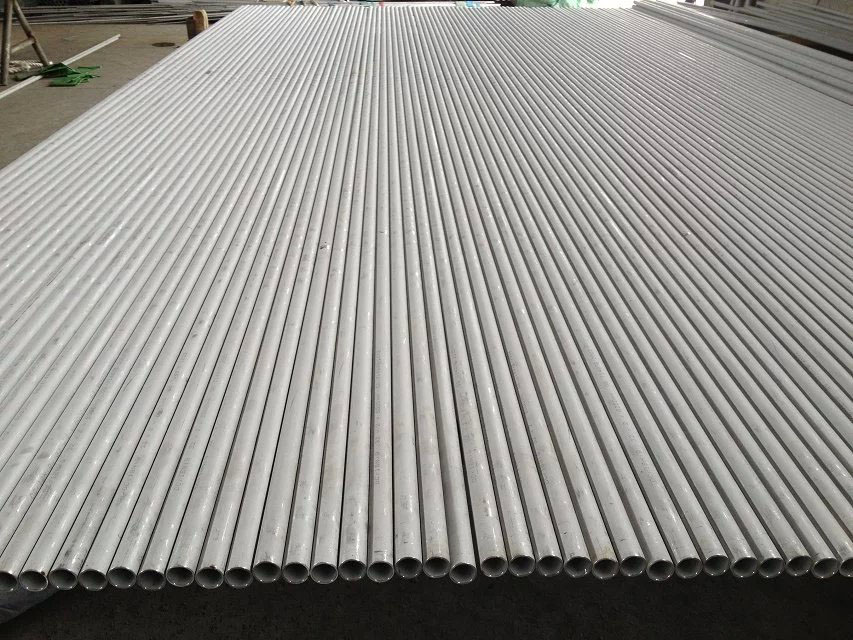

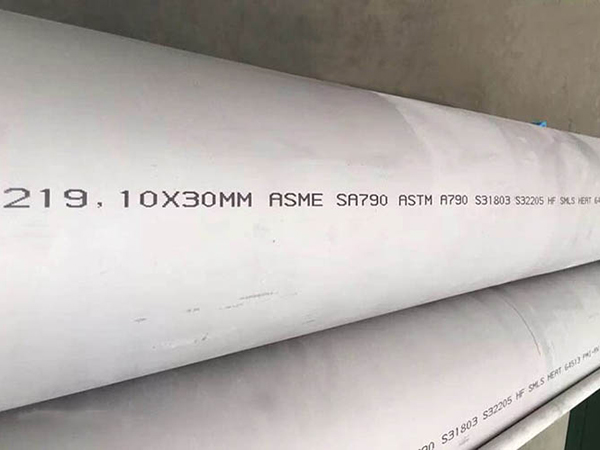

ASTM A312 Pipe

Products description:

Stainless steel pipe is primarily used in piping systems for the transport of fluids or gases. Stainless steel pipe resists oxidation, making it a low-maintenance solution that is suitable for high temperature and chemical applications. Because it is easily cleaned and sanitized, stainless steel pipe is also desired for applications involving food, beverages and pharmaceutical applications.

Chemical And Mechanical Properties

|

ASTM A312 Chemical and Mechanical Properties |

||||

|

ASTM A312 |

Chemical Composition |

|

||

|

C (Max) |

Mn |

Cr |

YIELD ( Min ) |

|

|

Mpa |

||||

|

TP201 |

0.15 |

5.5-7.5 |

16-18 |

260 |

|

TP304 |

0.08 |

2.00 |

18-20 |

205 |

|

TP304L |

0.035 |

2.00 |

18-20 |

170 |

|

TP304H |

0.1 |

2.00 |

18-20 |

205 |

|

TP304N |

0.08 |

2.00 |

18-20 |

240 |

|

TP309S |

0.08 |

2.00 |

22-24 |

205 |

|

TP309H |

0.1 |

2.00 |

22-24 |

205 |

|

TP310S |

0.08 |

2.00 |

24-26 |

205 |

|

TP310H |

0.1 |

2.00 |

24-26 |

205 |

|

TP316 |

0.08 |

2.00 |

16-18 |

205 |

|

TP316L |

0.035 |

2.00 |

16-18 |

170 |

|

TP316H |

0.1 |

2.00 |

16-18 |

205 |

|

TP316Ti |

0.08 |

2.00 |

16-18 |

205 |

|

TP316N |

0.08 |

2.00 |

16-18 |

240 |

|

TP317 |

0.08 |

2.00 |

18-20 |

205 |

|

TP317L |

0.035 |

2.00 |

18-20 |

205 |

|

TP321 |

0.08 |

2.00 |

17-19 |

205 |

|

TP321H |

0.1 |

2.00 |

17-19 |

205 |

|

TP347 |

0.08 |

2.00 |

17-19 |

205 |

|

TP347H |

0.1 |

2.00 |

17-19 |

205 |

|

TP348 |

0.08 |

2.00 |

17-19 |

205 |

|

TP348H |

0.1 |

2.00 |

17-19 |

205 |

ASTM A312 PIPE SCHEDULE CHART

DIMENSIONAL RANGE

|

NPS |

Outside Diameter |

ASTM A312 Pipe Schedule |

||

|

(in) |

(in) |

|||

|

|

|

SCH 10S |

SCH 40S |

SCH 80S |

|

|

|

Wall Thickness (mm) |

||

|

1/8 |

0.405 |

1.24 |

1.73 |

2.41 |

|

1/4 |

0.54 |

1.65 |

2.24 |

3.02 |

|

3/8 |

0.675 |

1.65 |

2.31 |

3.2 |

|

1/2 |

0.84 |

2.11 |

2.77 |

3.73 |

|

3/4 |

1.05 |

2.11 |

2.87 |

3.91 |

|

1 |

1.315 |

2.77 |

3.38 |

4.55 |

|

1 1/4 |

1.66 |

2.77 |

3.56 |

4.85 |

|

1 1/2 |

1.9 |

2.77 |

3.68 |

5.08 |

|

2 |

2.375 |

2.77 |

3.91 |

5.54 |

|

2 1/2 |

2.875 |

3.05 |

5.16 |

7.01 |

|

3 |

3.5 |

3.05 |

5.49 |

7.62 |

|

3 1/2 |

4 |

3.05 |

5.74 |

8.08 |

|

4 |

4.5 |

3.05 |

6.02 |

8.56 |

|

5 |

5.563 |

3.4 |

6.55 |

9.52 |

|

6 |

6.625 |

3.4 |

7.11 |

10.97 |

|

8 |

8.625 |

3.76 |

8.18 |

12.7 |

|

10 |

10.75 |

4.19 |

9.27 |

12.7 |

|

12 |

12.75 |

4.57 |

9.52 |

12.7 |

|

14 |

14 |

4.78 |

9.52 |

12.7 |

|

16 |

16 |

4.78 |

9.52 |

12.7 |

|

18 |

18 |

4.78 |

9.52 |

12.7 |

|

20 |

20 |

5.54 |

9.52 |

12.7 |

|

22 |

22 |

5.54 |

9.52 |

12.7 |

|

24 |

24 |

6.35 |

9.52 |

12.7 |

|

30 |

30 |

7.92 |

9.52 |

12.7 |

ASTM A312 PIPE WALL THICKNESS TOLERANCE (WT)

|

NPS Designator |

Tolerace,% from nominal |

|

1⁄8 to 21⁄2 incl., all t/D ratios |

+20%/-12.5% |

|

3 to 18 incl., t/D up to 5 % incl |

+22.5%/-12.5% |

|

3 to 18 incl., t/D > 5 % |

+15%/-12.5% |

|

20 and larger, welded, all t/D ratios |

+17.5%/-12.5% |

|

20 and larger, seamless, t/D up to 5 % incl. |

+22.5%/-12.5% |

|

20 and larger, seamless, t/D > 5 % |

+15%/-12.5% |