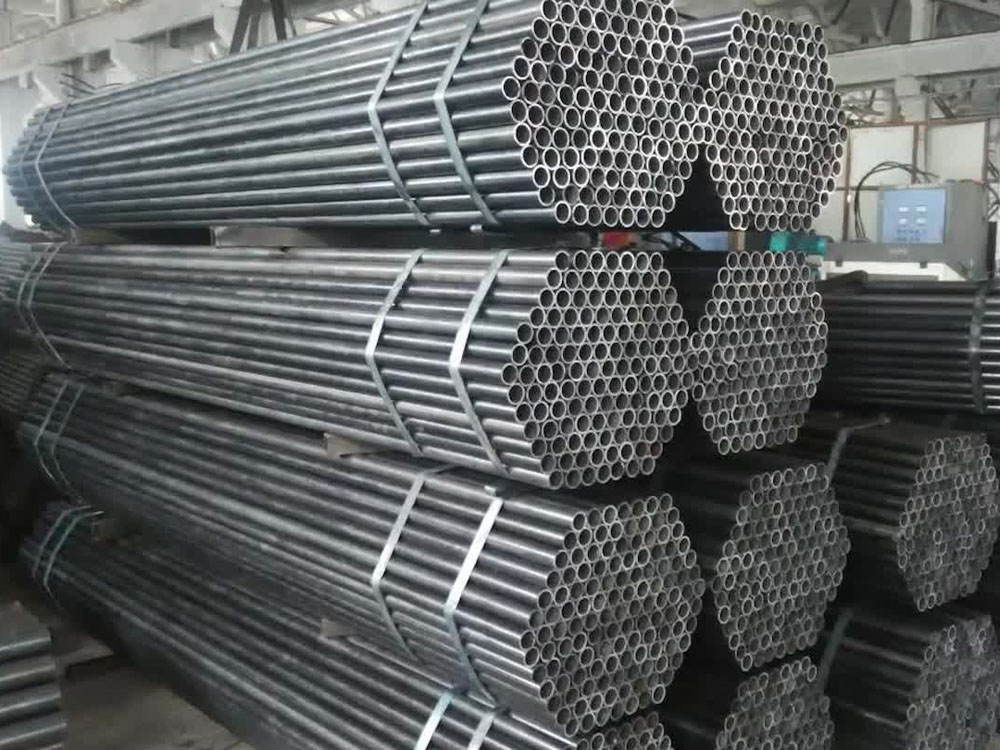

ASTM A213 Pipe

A213/SA213 alloy tubing grades are T5, T9, T11, T12, T22, T91, stainless tubing are TP304/304L, TP316/316L

Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes

Application:

These A213/SA213 are used in various application industry like Common industrial services (Petroleum, chemical, paper, fertilizer, fabric, aviation and nuclear) Fluid, gas and oil industry Heat transmission and pressure service ,Construction and ornamental,Boilers and Heat exchangers ,Decoration purpose, boiler, auto parts, medical device, food industry, building materials)

| Chemical Composition Limits, %A, for Low Alloy Steel | ||||||||||||||||

| Grade | UNS Designation |

Composition, % | ||||||||||||||

| Carbon | Manga- nese | Phospho- rus | Sul- fur | Silicon | Nickel | Chromium | Molybdenum | Vana- dium | Boron | Niobium | Nitrogen | Aluminum | Tungsten | Other Elements | ||

| T2 | K11547 | 0.10–0.20 | 0.30–0.61 | 0.025 | 0.025B | 0.10–0.30 | … | 0.50–0.81 | 0.44–0.65 | … | … | … | … | … | … | … |

| T5 | K41545 | 0.15 | 0.30–0.60 | 0.025 | 0.025 | 0.50 | … | 4.00–6.00 | 0.45–0.65 | … | … | … | … | … | … | … |

| T5b | K51545 | 0.15 | 0.30–0.60 | 0.025 | 0.025 | 1.00–2.00 | … | 4.00–6.00 | 0.45–0.65 | … | … | … | … | … | … | … |

| T5c | K41245 | 0.12 | 0.30–0.60 | 0.025 | 0.025 | 0.50 | … | 4.00–6.00 | 0.45–0.65 | … | … | … | … | … | … | Ti |

| 4xC–0.70 | ||||||||||||||||

| T9 | K90941 | 0.15 | 0.30–0.60 | 0.025 | 0.025 | 0.25–1.00 | … | 8.00–10.00 | 0.90–1.10 | … | … | … | … | … | … | … |

| T11 | K11597 | 0.05–0.15 | 0.30–0.60 | 0.025 | 0.025 | 0.50–1.00 | … | 1.00–1.50 | 0.44–0.65 | … | … | … | … | … | … | … |

| T12 | K11562 | 0.05–0.15 | 0.30–0.61 | 0.025 | 0.025B | 0.50 | … | 0.80–1.25 | 0.44–0.65 | … | … | … | … | … | … | … |

| T17 | K12047 | 0.15–0.25 | 0.30–0.61 | 0.025 | 0.025 | 0.15–0.35 | … | 0.80–1.25 | … | 0.15 | … | … | … | … | … | … |

| T21 | K31545 | 0.05–0.15 | 0.30–0.60 | 0.025 | 0.025 | 0.50–1.00 | … | 2.65–3.35 | 0.80–1.06 | … | … | … | … | … | … | … |

| T22 | K21590 | 0.05–0.15 | 0.30–0.60 | 0.025 | 0.025 | 0.50 | … | 1.90–2.60 | 0.87–1.13 | … | … | … | … | … | … | … |

| T23 | K40712 | 0.04–0.10 | 0.10–0.60 | 0.030 | 0.010 | 0.50 | 0.40 | 1.90–2.60 | 0.05–0.30 0.20–0.30 | 0.0010– | 0.02–0.08 | 0.015 | 0.030 | 1.45–1.75 Ti | ||

| 0.006 | 0.005–0.060 | |||||||||||||||

| Ti/N $ 3.5C |

||||||||||||||||

| T24 | K30736 | 0.05–0.10 | 0.30–0.70 | 0.020 | 0.010 | 0.15–0.45 | … | 2.20–2.60 | 0.90–1.10 0.20–0.30 | 0.0015– | … | 0.012 | 0.02 | … Ti | ||

| 0.007 | 0.06–0.10 | |||||||||||||||

| T36 | K21001 | 0.10–0.17 | 0.80–1.20 | 0.030 | 0.025 | 0.25–0.50 | 1.00–1.30 | 0.30 | 0.25–0.50 | 0.02 | … | 0.015–0.045 | 0.02 | 0.050 | … | Cu |

| 0.50–0.80 | ||||||||||||||||

| T91 | K90901 | 0.07–0.14 | 0.30–0.60 | 0.020 | 0.010 | 0.20–0.50 | 0.40 | 8.0–9.5 | 0.85–1.05 | 0.18–0.25 | … | 0.06–0.10 | 0.030– | 0.02 | … | Ti 0.01 |

| 0.070 | Zr 0.01 | |||||||||||||||

| T92 | K92460 | 0.07–0.13 | 0.30–0.60 | 0.020 | 0.010 | 0.50 | 0.40 | 8.5–9.5 | 0.30–0.60 | 0.15–0.25 | 0.001– | 0.04–0.09 | 0.030– | 0.02 | 1.5–2.00 | Ti 0.01 |

| 0.006 | 0.070 | Zr 0.01 | ||||||||||||||

| T122 | K91271 | 0.07–0.14 | 0.70 | 0.020 | 0.010 | 0.50 | 0.50 | 10.0–11.5 | 0.25–0.60 | 0.15–0.30 | 0.0005– | 0.04–0.10 | 0.040– | 0.02 | 1.50–2.50 | Cu |

| 0.005 | 0.100 | 0.30–1.70 | ||||||||||||||

| Ti 0.01 | ||||||||||||||||

| Zr 0.01 | ||||||||||||||||

| T911 | K91061 | 0.09–0.13 | 0.30–0.60 | 0.020 | 0.010 | 0.10–0.50 | 0.40 | 8.5–9.5 | 0.90–1.10 | 0.18–0.25 | 0.0003– | 0.06–0.10 | 0.040– | 0.02 | 0.90–1.10 | Ti 0.01 |

| 0.006 | 0.090 | Zr 0.01 | ||||||||||||||

| A Maximum, unless range or minimum is indicated. Where ellipses (…) appear in this table, there is no requirement, and analysis for the element need not be determined or reported. B It is permissible to order T2 and T12 with a sulfur content of 0.045 max. See 15.3. C Alternatively, in lieu of this ratio minimum, the material shall have a minimum hardness of 275 HV in the hardened condition, defined as after austenitizing and cooling to room temperature but prior to tempering. Hardness testing shall be performed at mid-thickness of the product. Hardness test frequency shall be two samples of product per heat treatment lot and the hardness testing results shall be reported on the material test report. |

||||||||||||||||

| Chemical Composition Limits, %A, for Austenitic and Ferritic Stainless Steel | |||||||||||||

| Grade | UNS Designation |

Composition, % | |||||||||||

| Carbon | Manga- nese | Phospho- rus | Sul- fur | Silicon | Chromium | Nickel | Molybdenum | Nitrogen B | Niobium | Tianium | Other Elements | ||

| TP201 | S20100 | 0.15 | 5.5-7.5 | 0.060 | 0.030 | 1.00 | 16.0-18.0 | 3.5-5.5 | … | 0.25 | … | … | … |

| TP202 | S20200 | 0.15 | 7.5-10.0 | 0.060 | 0.030 | 1.00 | 17.0-19.0 | 4.0-6.0 | … | 0.025 | … | … | … |

| XM-19C | S20910 | 0.06 | 4.0-6.0 | 0.045 | 0.030 | 1.00 | 20.5-23.5 | 11.5-13.5 | 1.5-3.00 | 0.20-0.40 | 0.10-0.30 | … | V 0.10-0.30 |

| C | S21500 | 0.06–0.15 | 5.5–7.0 | 0.045 | 0.030 | 0.20–1.00 | 14.0–16.0 | 9.0–11.0 | 0.80–1.20 | … | 0.75–1.25 | … | B 0.003– |

| 0.009, | |||||||||||||

| V 0.15–0.40 | |||||||||||||

| C | S25700 | 0.02 | 2.00 | 0.025 | 0.010 | 6.5–8.0 | 8.0–11.5 | 22.0–25.0 | 0.50 | … | … | … | … |

| TP304 | S30400 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 18.0–20.0 | 8.0–11.0 | … | … | … | … | … |

| TP304L | S30403 | 0.035D | 2.00 | 0.045 | 0.030 | 1.00 | 18.0–20.0 | 8.0–12.0 | … | … | … | … | … |

| TP304H | S30409 | 0.04–0.10 | 2.00 | 0.045 | 0.030 | 1.00 | 18.0–20.0 | 8.0–11.0 | … | … | … | … | … |

| C | S30432 | 0.07–0.13 | 1.00 | 0.040 | 0.010 | 0.30 | 17.0–19.0 | 7.5–10.5 | … | 0.05–0.12 | 0.30–0.60 | … | Al 0.003– |

| 0.030, | |||||||||||||

| B 0.001– | |||||||||||||

| 0.010, | |||||||||||||

| Cu 2.5–3.5 | |||||||||||||

| C | S30434 | 0.07–0.14 | 2.00 | 0.040 | 0.010 | 1.00 | 17.5–19.5 | 9.0–12.0 | … | … | 0.10–0.40E | 0.10–0.25E | B 0.001– |

| 0.004 | |||||||||||||

| Cu 2.50– | |||||||||||||

| 3.50 | |||||||||||||

| TP304N | S30451 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 18.0–20.0 | 8.0–11.0 | … | 0.10–0.16 | … | … | … |

| TP304LN | S30453 | 0.035D | 2.00 | 0.045 | 0.030 | 1.00 | 18.0–20.0 | 8.0–11.0 | … | 0.10–0.16 | … | … | … |

| C | S30615 | 0.016–0.24 | 2.00 | 0.030 | 0.030 | 3.2–4.0 | 17.0–19.5 | 13.5–16.0 | … | … | … | … | Al 0.8–1.5 |

| C | S30815 | 0.05–0.10 | 0.80 | 0.040 | 0.030 | 1.40–2.00 | 20.0–22.0 | 10.0–12.0 | … | 0.14–0.20 | … | … | Ce 0.03–0.08 |

| TP309S | S30908 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 22.0–24.0 | 12.0–15.0 | … | … | … | … | … |

| TP309H | S30909 | 0.04–0.10 | 2.00 | 0.045 | 0.030 | 1.00 | 22.0–24.0 | 12.0–15.0 | … | … | … | … | … |

| TP309LMoN | S30925 | 0.025 | 2.00 | 0.040 | 0.030 | 0.70 | 23.0–26.0 | 13.0–16.0 | 0.5–1.2 | 0.25–0.40 | … | … | … |

| TP309Cb | S30940 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 22.0–24.0 | 12.0–16.0 | … | … | 10xC–1.10 | … | … |

| TP309HCb | S30941 | 0.04–0.10 | 2.00 | 0.045 | 0.030 | 1.00 | 22.0–24.0 | 12.0–16.0 | … | … | 10xC-1.10 | … | … |

| … | S30942 | 0.03–0.10 | 2.00 | 0.040 | 0.030 | 1.00 | 21.0–23.0 | 14.5–16.5 | 0.10–0.20 | 0.50–0.80 | B=0.001–0.005 | ||

| C | S31002 | 0.02 | 2.00 | 0.020 | 0.015 | 0.15 | 24.0–26.0 | 19.0–22.0 | 0.10 | 0.10 | … | … | … |

| TP310S | S31008 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 24.0–26.0 | 19.0–22.0 | … | … | … | … | … |

| TP310H | S31009 | 0.04–0.10 | 2.00 | 0.045 | 0.030 | 1.00 | 24.0–26.0 | 19.0–22.0 | … | … | … | … | … |

| TP310MoCbN | S31025 | 0.10 | 1.50 | 0.030 | 0.030 | 1.00 | 19.5–23.0 | 23.0–26.0 | 1.0–2.0 | 0.10–0.25 | 0.10–0.40 | 0.20 | B 0.002– |

| 0.010 | |||||||||||||

| S31035 | 0.04–0.10 | 0.60 | 0.030 | 0.015 | 0.40 | 21.5–23.5 | 23.5–26.5 | … | 0.15–0.30 | 0.30–0.60 | … | W 2.0–4.0 | |

| Co 1.0–2.0 | |||||||||||||

| Cu 2.0–3.5 | |||||||||||||

| B 0.002– | |||||||||||||

| 0.008 | |||||||||||||

| TP310Cb | S31040 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 24.0–26.0 | 19.0–22.0 | … | … | 10xC-1.10 | … | … |

| TP310HCb | S31041 | 0.04–0.10 | 2.00 | 0.045 | 0.030 | 1.00 | 24.0–26.0 | 19.0–22.0 | … | … | 10xC-1.10 | … | … |

| TP310HCbN | S31042 | 0.04–0.10 | 2.00 | 0.045 | 0.030 | 1.00 | 24.0–26.0 | 19.0–22.0 | … | 0.15–0.35 | 0.20–0.60 | … | … |

| TP310MoLN | S31050 | 0.025 | 2.00 | 0.020 | 0.030 | 0.40 | 24.0–26.0 | 21.0–23.0 | 2.00–3.00 | 0.10–0.16 | … | … | … |

| C | S31060 | 0.05–0.10 | 1.00 | 0.040 | 0.030 | 0.50 | 22.0–24.0 | 10.0–12.5 | … | 0.18–0.25 | … | … | Ce + La |

| 0.025–0.070 | |||||||||||||

| B 0.001–0.010 | |||||||||||||

| C | S31254 | 0.020 | 1.00 | 0.030 | 0.010 | 0.80 | 19.5–20.5 | 17.5–18.5 | 6.0–6.5 | 0.18–0.22 | … | … | Cu 0.50–1.00 |

| C | S31272 | 0.08–0.12 | 1.50–2.00 | 0.030 | 0.015 | 0.30–0.70 | 14.0–16.0 | 14.0–16.0 | 1.00–1.40 | … | … | 0.30–0.60 | B 0.004– |

| 0.008 | |||||||||||||

| C | S31277 | 0.020 | 3.00 | 0.030 | 0.010 | 0.50 | 20.5–23.0 | 26.0–28.0 | 6.5–8.0 | 0.30–0.40 | … | … | Cu 0.50–1.50 |

| TP316 | S31600 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 16.0–18.0 | 10.0–14.0 | 2.00–3.00 | … | … | … | … |

| TP316L | S31603 | 0.035D | 2.00 | 0.045 | 0.030 | 1.00 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 | … | … | … | … |

| TP316H | S31609 | 0.04-0.10 | 2.00 | 0.045 | 0.030 | 1.00 | 16.0-18.0 | 11.0-14.0 | 2.00-3.00 | … | … | … | … |

| TP316Ti | S31635 | 0.08–0.12 | 2.00 | 0.045 | 0.030 | 0.75 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 | 0.1 | … | 5X | |

| (C + N)– 0.70 |

|||||||||||||

| TP316N | S31651 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 16.0-18.0 | 10.0-13.0 | 2.00-3.00 | 0.10-0.16 | … | … | … |

| TP316LN | S31653 | 0.035D | 2.00 | 0.045 | 0.030 | 1.00 | 16.0-18.0 | 10.0-13.0 | 2.00-3.00 | 0.10-0.16 | … | … | … |

| TP317 | S31700 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 18.0-20.0 | 11.0-15.0 | 3.0-4.0 | … | … | … | … |

| TP317L | S31703 | 0.035 | 2.00 | 0.045 | 0.030 | 1.00 | 18.0-20.0 | 11.0-15.0 | 3.0-4.0 | … | … | … | … |

| TP317LM | S31725 | 0.03 | 2.00 | 0.045 | 0.030 | 1.00 | 18.0-20.0 | 13.5-17.5 | 4.0-5.0 | 0.2 | … | … | Cu 0.75 |

| TP317LMN | S31726 | 0.03 | 2.00 | 0.045 | 0.030 | 1.00 | 17.0-20.0 | 13.5-17.5 | 4.0-5.0 | 0.10-0.20 | … | … | Cu 0.75 |

| C | S32050 | 0.030 | 1.50 | 0.035 | 0.020 | 1.00 | 22.0–24.0 | 20.0–23.0 | 6.0–6.8 | 0.21–0.32 | … | … | Cu 0.40 |

| TP321 | S32100 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 17.0–19.0 | 9.0–12.0 | … | … | … | 5(C + N)– | … |

| 0.70 | |||||||||||||

| TP321H | S32109 | 0.04–0.10 | 2.00 | 0.045 | 0.030 | 1.00 | 17.0–19.0 | 9.0–12.0 | … | … | … | 4(C + N)– | … |

| C | S32615 | 0.07 | 2.00 | 0.045 | 0.030 | 4.8–6.0 | 16.5–19.5 | 19.0–22.0 | 0.30–1.50 | … | 0.70 | Cu 1.50– 2.50 |

|

| C | S33228 | 0.04–0.08 | 1.00 | 0.020 | 0.015 | 0.30 | 26.0–28.0 | 31.0–33.0 | … | … | 0.60–1.00 | … | Ce 0.05– 0.10, Al 0.025 |

| C | S33229 | 0.04–0.09 | 2.00 | 1.020 | 1.015 | 1.30 | 26.0–28.1 | 31.0–33.1 | … | … | 0.60–1.01 | … | Ce 0.05– 0.10, Al 0.026 |

| TP347 | S34700 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 17.0–20.0 | 9.0–13.0 | … | … | 10xC-1.10 | … | … |

| TP347W | S34705 | 0.05 | 2.00 | 0.040 | 0.030 | 1.00 | 17.0–20.0 | 8.00–11.0 | … | 0.10–0.25 | 0.25-0.50 | … | V 0.20–0.50 |

| W 1.50–2.60 | |||||||||||||

| TP347H | S34709 | 0.04–0.10 | 2.00 | 0.045 | 0.030 | 1.00 | 17.0–19.0 | 9.0–13.0 | … | … | 8xC-1.10 | … | … |

| TP347HFG | S34710 | 0.06–0.10 | 2.00 | 0.045 | 0.030 | 1.00 | 17.0–19.0 | 9.0–13.0 | … | … | 8xC-1.10 | … | … |

| TP347LN | S34751 | 0.005–0.020 | 2.00 | 0.045 | 0.030 | 1.00 | 17.0–19.0 | 9.0–12.0 | … | 0.06–0.10 | 0.20-0.50F | … | … |

| TP348 | S34800 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 17.0–19.0 | 9.0–13.0 | … | … | G | … | Co 0.20, Ta 0.10 |

| TP348H | S34809 | 0.04–0.10 | 2.00 | 0.045 | 0.030 | 1.00 | 17.0–19.0 | 9.0–13.0 | … | … | H | … | Co 0.20, Ta 0.10 |

| … | S35045 | 0.06–0.10 | 1.50 | 0.045 | 0.015 | 1.00 | 25.0–29.0 | 32.0–37.0 | … | … | … | 0.15-0.60 | Al 0.15–0.60 Cu 0.75 |

| XM-15 | S38100 | 0.08 | 2.00 | 0.030 | 0.030 | 1.50–2.50 | 17.0–19.0 | 17.5–18.5 | … | … | … | … | … |

| … | S38815 | 0.030 | 2.00 | 0.040 | 0.020 | 5.5–6.5 | 13.0–15.0 | 15.0–17.0 | 0.75–1.50 | … | … | … | Cu 0.75–1.50 Al 0.30 |

| 800 | N08800 | 0.10 | 1.50 | 0.045 | 0.015 | 1.00 | 19.0–23.0 | 30.0–35.0 | … | … | Al 0.15–0.60 | ||

| Ti 0.15–0.60 | |||||||||||||

| FeI 39.5 min | |||||||||||||

| 800H | N08810 | 0.05-0.10 | 1.50–2.00 | 0.045 | 0.015 | 1 | 19.0-23.0 | 30.0-35.0 | … | … | Cu 0.75 Al 0.15–0.60 Ti 0.15–0.60 FeI 39.5 min |

||

| N08811 | 0.06-0.10 | 1.50–2.00 | 0.045 | 0.015 | 1 | 19.0-23.0 | 30.0-35.0 | … | … | Cu 0.75 Al 0.15–0.60J Ti 0.15–0.60J FeI 39.5 min |

|||

| N08904 | 0.02 | 2 | 0.04 | 0.03 | 1 | 19.0-23.0 | 23.0-28.0 | 4.0-5.0 | 0.1 | Cu 1.00–2.00 | |||

| N08925 | 0.02 | 1 | 0.045 | 0.03 | 0.5 | 19.0-21.0 | 24.0-26.0 | 6.0-7.0 | 0.10-0.20 | … | … | Cu 0.80-1.50 | |

| N08926 | 0.02 | 2 | 0.03 | 0.01 | 0.5 | 19.0-21.0 | 24.0-26.0 | 6.0-7.0 | 0.15-0.25 | … | … | Cu 0.80-1.50 | |

| TP444 | S44400 | 0.03 | 1 | 0.04 | 0.03 | 1 | 17.5-19.5 | K | 1.75-2.50 | 0.035 | … | L | … |

| AMaximum, unless a range or minimum is indicated. Where ellipses (…) appear in this table, there is no minimum and analysis for the element need not be determined or reported. BThe method of analysis for Nitrogen shall be a matter of agreement between the purchaser and the producer. CFor these alloys, there is no common grade designation. The UNS number uniquely identifies these alloys. DFor small diameter or thin walls, or both, where many drawing passes are required, a carbon maximum of 0.040% is necessary in Grades TP304L, TP304LN, TP316L, and TP316LN. EGrade S30434 shall have (Ti + 1⁄2 Nb) of not less than 2 times and not more than 4 times the carbon content. FGrade TP347LN shall have an Nb content of not less than 15 times the carbon content. GGrade TP348 shall have an Nb + Ta content of not less than 10 times the carbon content and not more than 1.10%. HGrade TP348H shall have an Nb + Ta content of not less than 8 times the carbon content and not more than 1.10%. IIron shall be determined arithmetically by difference of 100 minus the sum of the other specified elements. J(Al + Ti) 0.85–1.20. KGrade TP444 shall have Ni + Cu = 1.00 max. LGrade TP444 shall have Ti + Nb = 0.20 + 4(C + N)–0.80. |

|||||||||||||

| Tensile and Hardness Requirements | ||||||

| Grade | UNS | Tensile Strength, | Yield Strength, | Elongation in 2 in. or | HardnessA | |

| Designation | min, ksi | min, ksi | 50 mm, | Brinell/Vickers | Rockwell | |

| [MPa] | [MPa] | min, %B,C | ||||

| Low Alloy Steels: T5b |

K51545 | 60 [415] | 30 [205] | 30 | 179 HBW/ | 89 HRB |

| T9 | K90941 | 60 [415] | 30 [205] | 30 | 190HV 179 HBW/ |

89 HRB |

| T12 | K11562 | 60 [415] | 32 [220] | 30 | 190HV 163 HBW/ |

85 HRB |

| T23 | K40712 | 74 [510] | 58 [400] | 20 | 170 HV 220 HBW/ |

97 HRB |

| T24 | K30736 | 85 [585] | 60 [415] | 20 | 230 HV 250 HBW/ |

25 HRC |

| T36 Class 1 | K21001 | 90 [620] | 64 [440] | 15 | 265 HV 250 HBW/ |

25 HRC |

| T36 Class 2 | K21001 | 95.5 [660] | 66.5 [460] | 15 | 265 HV 250 HBW/ |

25 HRC |

| T91 | K90901 | 85 [585] | 60 [415] | 20 | 265 HV 190 to 250 HBW/ |

90 HRB to 25 |

| T92 | K92460 | 90 [620] | 64 [440] | 20 | 196 to 265 HV 250 HBW/ |

HRC 25 HRC |

| T122 | K91271 | 90 [620] | 58 [400] | 20 | 265 HV 250 HBW/ |

25 HRC |

| T911 | K91061 | 90 [620] | 64 [440] | 20 | 265 HV 250 HBW/ |

25 HRC |

| 265 HV | ||||||

| All other low alloy grades | 60 [415] | 30 [205] | 30 | 163 HB/ 170 HV |

85 HRB | |

| Austenitic Stainless Steels: TP201 |

S20100 | 95 [655] | 38 [260] | 35 | 219 HBW/ | 95 HRB |

| TP202 | S20200 | 90 [620] | 45 [310] | 35 | 230 HV 219 HBW/ |

95 HRB |

| XM-19 | S20910 | 100 [690] | 55 [380] | 35 | 230 HV 250 HBW/ |

25 HRC |

| … | S21500 | 78 [540] | 33 [230] | 35 | 265 HV 192 HBW/ |

90 HRB |

| … | S25700 | 78 [540] | 35 [240] | 50 | 200 HV 217 HBW |

95 HRB |

| TP304 | S30400 | 75 [515] | 30 [205] | 35 | 192 HBW/ | 90 HRB |

| TP304L | S30403 | 70 [485] | 25 [170] | 35 | 200 HV 192 HBW/ |

90 HRB |

| TP304H | S30409 | 75 [515] | 30 [205] | 35 | 200 HV 192 HBW/ |

90 HRB |

| … | S30432 | 86 [590] | 34 [235] | 35 | 200 HV 219 HBW/ |

95 HRB |

| … | S30434 | 73 [500] | 30 [205] | 35 | 230 HV 192 HBW/ |

90 HRB |

| TP304N | S30451 | 80 [550] | 35 [240] | 35 | 200 HV 192 HBW/ |

90 HRB |

| TP304LN | S30453 | 75 [515] | 30 [205] | 35 | 200 HV 192 HBW/ |

90 HRB |

| … | S30615 | 90 [620] | 40 [275] | 35 | 200 HV 192 HBW/ |

90 HRB |

| … | S30815 | 87 [600] | 45 [310] | 40 | 200 HV 217 HBW |

95 HRB |

| TP309S | S30908 | 75 [515] | 30 [205] | 35 | 192 HBW/ | 90 HRB |

| TP309H | S30909 | 75 [515] | 30 [205] | 35 | 200 HV 192 HBW/ |

90 HRB |

| TP309LMoN | S30925 | 93 [640] | 38 [260] | 30 | 200 HV 256 HBW/270 HV |

100 HRB |

| TP309Cb | S30940 | 75 [515] | 30 [205] | 35 | 192 HBW/ | 90 HRB |

| TP309HCb | S30941 | 75 [515] | 30 [205] | 35 | 200 HV 192 HBW/ |

90 HRB |

| … | S30942 | 86 [590] | 34 [235] | 35 | 200 HV 219 HBW/ |

95 HRB |

| 230 HV | ||||||

| … | S31002 | 73 [500] | 30 [205] | 35 | 192 HBW/ | 90 HRB |

| 200 HV | ||||||

| TP310S | S31008 | 75 [515] | 30 [205] | 35 | 192 HBW/ | 90 HRB |

| 200 HV | ||||||

| TP310H | S31009 | 75 [515] | 30 [205] | 35 | 192 HBW/ | 90 HRB |

| 200 HV | ||||||

| TP310MoCbN | S31025 | 93 [640] | 39 [270] | 30 | 256 HBW/ | 100 HRB |

| 270 HV | ||||||

| S31035 | 95 [655] | 45 [310] | 40 | 220 HBW/ | 96 HRB | |

| 230 HV | ||||||

| TP310Cb | S31040 | 75 [515] | 30 [205] | 35 | 192 HBW/ | 90 HRB |

| 200 HV | ||||||

| TP310HCb | S31041 | 75 [515] | 30 [205] | 35 | 192 HBW/ | 90 HRB |

| 200 HV | ||||||

| TP310HCbN | S31042 | 95 [655] | 43 [295] | 30 | 256 HBW | 100 HRB |

| TP310MoLN | S31050 | |||||

| T # 0.25 in. [6 mm] | 84 [580] | 39 [270] | 25 | 217 HBW | 95 HRB | |

| t > 0.25 in. [6 mm] | 78 [540] | 37 [255] | 25 | 217 HBW | 95 HRB | |

| … | S31060 | 87 [600] | 41 [280] | 40 | 217 HBW | 95 HRB |

| … | S31254 | |||||

| T # 0.187 in. [5 mm] | 98 [675] | 45 [310] | 35 | 220 HBW/ | 96 HRB | |

| 230 HV | ||||||

| T > 0.187 in. [5 mm] | 95 [655] | 45 [310] | 35 | 220 HBW/ | 96 HRB | |

| 230 HV | ||||||

| … | S31272 | 65 [450] | 29 [200] | 35 | 217 HBW | 95 HRB |

| … | S31277 | 112 [770] | 52 [360] | 40 | 241 HBW | 100 HRB |

| TP316 | S31600 | 75 [515] | 30 [205] | 35 | 192 HBW/ | 90 HRB |

| 200 HV | ||||||

| TP316L | S31603 | 70 [485] | 25 [170] | 35 | 192 HBW/ | 90 HRB |

| 200 HV | ||||||

| TP316H | S31609 | 75 [515] | 30 [205] | 35 | 192 HBW/ | 90 HRB |

| 200 HV | ||||||

| TP316Ti | S31635 | 75 [515] | 30 [205] | 35 | 192 HBW/ | 90 HRB |

| 200 HV | ||||||

| TP316N | S31651 | 80 [550] | 35 [240] | 35 | 192 HBW/ | 90 HRB |

| 200 HV | ||||||

| TP317 | S31700 | 75 [515] | 30 [205] | 34 | 192 HBW/ | 90 HRB |

| 200 HV | ||||||

| TP317L | S31703 | 75 [515] | 30 [205] | 35 | 192 HBW/ | 90 HRB |

| 200 HV | ||||||

| … | S31725 | 75 [515] | 30 [205] | 35 | 192 HBW/ | 90 HRB |

| 200 HV | ||||||

| … | S32050 | 98 [675] | 48 [330] | 40 | 256 HBW | 100 HRB |

| TP321 | S32100 | 75 [515] | 30 [205] | 35 | 192 HBW/ | 90 HRB |

| 200 HV | ||||||

| TP321H | S32109 | 75 [515] | 30 [205] | 35 | 192 HBW/ | 90 HRB |

| 200 HV | ||||||

| … | S32615 | 80 [550] | 32 [220] | 25 | 192 HBW/ | 90 HRB |

| 200 HV | ||||||

| … | S32716 | 80 [240] | 35 [240] | 35 | 192 HBW/ | 90 HRB |

| 200 HV | ||||||

| … | S33228 | 73 [500] | 27 [185] | 30 | 192 HBW/ | 90 HRB |

| 200 HV | ||||||

| … | S34565 | 115 [790] | 60 [415] | 35 | 241 HBW | 100 HRB |

| TP347 | S34700 | 75 [515] | 30 [205] | 35 | 192 HBW/ | 90 HRB |

| 200 HV | ||||||

| TP347W | S34705 | 90 [620] | 38 [260] | 30 | 219 HBW/ | 95 HRB |

| 230 HV | ||||||

| TP347H | S34709 | 75 [515] | 30 [205] | 35 | 192 HBW/ | 90 HRB |

| 200 HV | ||||||

| TP347HFG | S34710 | 80 [550] | 30 [205] | 35 | 192 HBW/ | 90 HRB |

| 200 HV | ||||||

| TP347LN | S34751 | 75 [515] | 30 [205] | 35 | 192 HBW/ | 90 HRB |

| 200 HV | ||||||

| TP348 | S34800 | 75 [515] | 30 [205] | 35 | 192 HBW/ | 90 HRB |

| 200 HV | ||||||

| TP348H | S34809 | 75 [515] | 30 [205] | 35 | 192 HBW/ | 90 HRB |

| 200 HV | ||||||

| … | S35045 | 70 [485] | 25 [170] | 35 | 192 HBW/ | 90 HRB |

| 200 HV | ||||||

| XM-15 | S38100 | 75 [515] | 30 [205] | 35 | 192 HBW/ | 90 HRB |

| … | S38815 | 78 [540] | 37 [255] | 30 | 200 HV 256 HBW |

100 HRB |

| 800 | N08800 cold-worked |

75 [515] | 30 [205] | 30 | 192 HBW/ | 90 HRB |

| annealed hot-finished |

65 [450] | 25 [170] | 30 | 200 HV 192 HBW/ |

90 HRB | |

| 800H | annealed N08810 |

65 [450] | 25 [170] | 30 | 200 HV 192 HBW/ |

90 HRB |

| … | N08811 | 65 [450] | 25 [170] | 30 | 200 HV 192 HBW/ |

90 HRB |

| N08904 | 71 [490] | 31 [215] | 35 | 200 HV 192 HBW/ |

90 HRB | |

| … | N08925 | 87 [600] | 43 [295] | 40 | 200 HV 217 HBW |

95 HRB |

| … | N08926 | 94 [650] | 43 [295] | 35 | 256 HBW | 100 HRB |

| Ferritic Stainless Steels TP444 | S44400 | 60[415] | 40[275] | 20 | 217 HBW/ 230 HV | 96 HRB |

| A Max, unless a range or a minimum is specified. B When standard round 2 in. or 50 mm gage length or smaller proportionally sized specimens with gage length equal to 4D (4 times the diameter) is used, the minimum elongation shall be 22 % for all low alloy grades except T23, T24, T91, T92, T122, and T911; and except for TP444. C For longitudinal strip tests, a deduction from the basic minimum elongation values of 1.00 % for TP444, T23, T24, T91, T92, T122, and T911, and of 1.50 % for all other low alloy grades for each 1⁄32-in. [0.8-mm] decrease in wall thickness below 5⁄16 in. [8 mm] shall be made. |

||||||

| Computed Minmum ValuesA | ||||

| Wall Thickness | Elongation in 2in or 50 mm, min,% | |||

| in. | mm | S44400, T23, T24, T91, | T 36 | All Other |

| T92, T122, and | Ferritic Grades | |||

| T911 | ||||

| 5⁄16 [0.312] | 8 | 20 | 15 | 30 |

| 9⁄32 [0.281] | 7.2 | 19 | 14 | 29 |

| 1⁄4 [0.250] | 6.4 | 18 | 13 | 27 |

| 7⁄32 [0.219] | 5.6 | 17 | 12 | 26 |

| 3⁄16 [0.188] | 4.8 | 16 | 11 | 24 |

| 5⁄32 [0.156] | 4 | 15 | 10 | 23 |

| 1⁄8 [0.125] | 3.2 | 14 | 9 | 21 |

| 3⁄32 [0.094] | 2.4 | 13 | 8 | 20 |

| 1⁄16 [0.062] | 1.6 | 12 | 7 | 18 |

| 0.062 to 0.035, excl | 1.6 to 0.9 | 12 | 7 | 17 |

| 0.035 to 0.022, excl | 0.9 to 0.6 | 11 | 6 | 17 |

| 0.022 to 0.015 incl | 0.6 to 0.4 | 11 | 6 | 16 |

| A Calculated elongation requirements shall be rounded to the nearest whole number. | ||||

| Permitted Variations in Average Wall Thickness for Hot Formed Tubes | ||

| NPS [DN] Designator | Tolerance in Over | %, from specified Under |

| 1⁄8 to 21⁄2 [6 to 65] incl, all t/D ratiosA | 20 | 12.5 |

| Above 21⁄2 [65], t/D # 5 %A | 22.5 | 12.5 |

| Above 21⁄2 [65], t/D > 5 %A | 15 | 12.5 |

| A t = specified wall thickness D = specified outside diameter | ||

| Number of Tubes in a Lot Heat Treated by the Continuous Process or by Direct Quench After Hot Forming | |

| Size of Tube | Size of Lot |

| 2 in. [50.8 mm] and over in outside diameter and 0.200 in. [5.1 mm] and over in wall thickness 2 in. [50.8 mm] and over in outside diameter and under 0.200 in. [5.1 mm] in wall thickness Less than 2 in. [50.8 mm] but over 1 in. [25.4 mm] in outside diameter 1 in. [25.4 mm] or less in outside diameter |

not more than 50 tubes not more than 75 tubes not more than 75 tubes not more than 125 tubes |

Write your message here and send it to us